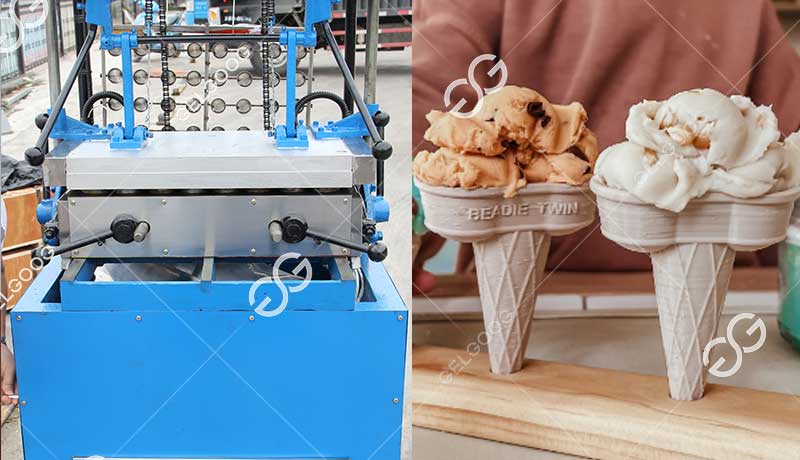

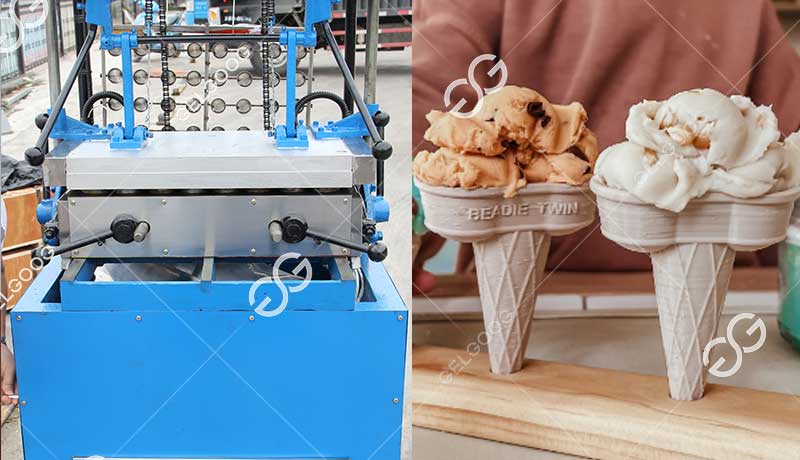

The small tabletop double-headed ice cream cone machine is an efficient and convenient equipment, which is widely used in ice cream shops, cafes, large kitchens and other places. The following is a detailed introduction to this equipment:

Double Headed Cone Machine Workflow

- Equipment inspection and preparation: Before starting the equipment, check whether the power supply, heating elements and molds of the machine are in good condition to ensure the safe operation of the equipment. Confirm that the surface of the baking tray is clean and free of residue to ensure product quality.

- Preheating equipment: Turn on the power of the equipment and preheat the baking tray to the set temperature. The preheating time depends on the equipment model and ambient temperature, generally 5-10 minutes. During the preheating process, ensure that the temperature is evenly distributed.

- Apply anti-stick coating: Apply a small amount of edible oil or special anti-stick spray evenly on the surface of the baking tray to prevent the batter from sticking. This step ensures smooth demoulding of the cone while avoiding burning of the batter.

- Batter preparation and quantitative injection: Pour the prepared batter into the grouting device of the equipment.

- Mold baking: Cover the upper mold and start baking, usually for 1-2 minutes. During the baking process, the heating system of the equipment ensures that the heat is evenly distributed, so that the cone is heated evenly.

- Molding and cooling: After baking, open the mold, the molded cone will slide naturally, and the complete cone will be collected through the collection channel.

Double Ice Cream Cone Machine Equipment Features

- Small size and easy operation: small desktop ice cream cone manufacturing equipment usually adopts a compact design, occupies a small area, and is suitable for use in limited space. The operation process of the equipment is simple and intuitive, and even novices can master it in a short time.

- Versatility: It can produce various types of ice cream cones. By changing the mold, users can flexibly adjust the product type according to market demand. Not only can it produce traditional flat cones, but also can make lace cones, bowl-shaped cups and other shapes and sizes of cones.

- Hygiene and Safety: All components that interact with food are constructed from food-grade stainless steel, ensuring compliance with sanitary standards and facilitating easy cleaning and maintenance. This material is resistant to corrosion, simple to clean, and effectively inhibits bacterial growth, thereby guaranteeing the cleanliness and safety of the production process.

- Efficient energy saving: The equipment adopts advanced heating technology and energy-saving design, which can reach the ideal baking temperature in a short time. The energy-saving characteristics effectively reduce energy consumption and reduce operating costs.

Our double ice cream cone machine is perfectly suited for ice cream shops and small factories, thanks to its efficiency, ease of use, and convenience. We remain dedicated to offering top-notch products and services, ensuring that you can quickly begin production and operate with confidence and ease.

Choosing our equipment, you will get not only high-quality products, but also a caring and professional service experience. Thank you for your choice and look forward to creating a better future with you!