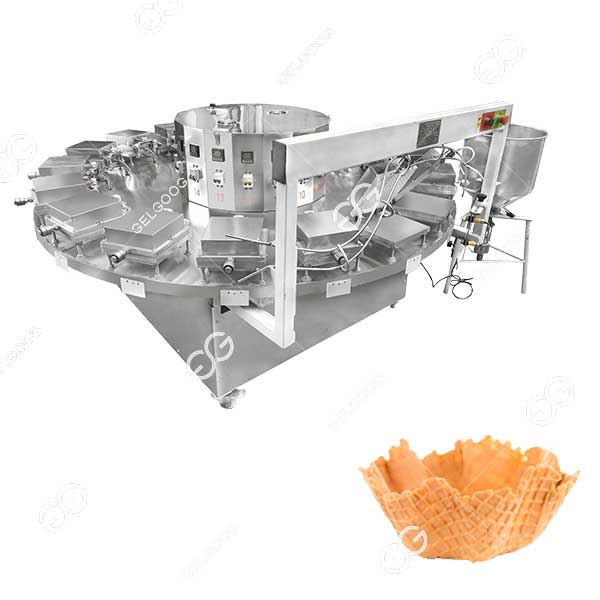

The Waffle Basket Making Machine is a food processing machine specifically designed for the continuous and automatic production of edible waffle baskets or bowls. It is widely used in ice cream shops, dessert factories, cafes, chain restaurants, and other locations.

Product Functions and Components

Function: Rapidly forms bowl-, basket-, or cup-shaped waffle shells from prepared waffle batter through metered pouring, double-sided baking, and hot pressing. These shells can be directly used to hold ice cream, fruit, yogurt, and more.

Components:

- Waffle Storage Tank: Maintains batter at a constant temperature and features stirring to prevent settling.

- Continuous Baking Station: Multiple aluminum alloy or non-stick baking molds, gas or electric heating.

- Automatic Forming Station: Presses the baked round waffle sheets into the desired three-dimensional shape while still hot using a robotic arm or mold.

- Cooling and Output: Fans provide rapid cooling and shaping, followed by automatic stacking or manual collection.

Waffle Basket Making Machine Advantages

- High Production Capacity and Scalability: Multiple units can be connected in parallel to form a continuous production line, meeting the needs of various scales, from retail stores to industrial-scale operations.

- Multiple Formats and Quick Mold Changeover: The same machine can produce a variety of edible containers, including bowls, baskets, cups, cones, and pizza cones, simply by changing molds. Adjustable diameters range from 90–170 mm, enabling stores to quickly update new products and reduce redundant equipment investment.

- Food-Grade Materials for Easy Cleaning: The entire machine features a 304 stainless steel frame and non-stick-coated baking molds for corrosion and stick resistance. The molds can be removed and rinsed completely.

- Precise Temperature Control and Stable Quality: Advanced PID or PLC temperature control ensures consistent thickness, color, and crispness for each waffle, reducing defective product rates. Temperature profiles can be configured with one click for different recipes (gluten-free, chocolate, whole wheat, etc.).

- Fully Automated Production Process: The machine integrates batter conveying, forming, baking, demolding, and stacking, enabling continuous operation. From raw material input to finished product output, manual intervention is unnecessary, reducing labor costs and preventing human error.

Applicable Product Forms

The same machine can produce the following by simply changing the mold:

- Waffle bowls, waffle baskets, waffle cups

- Ice cream cones, egg rolls, pizza cones, wafer cones

The Waffle Basket Making Machine is a highly efficient device that directly transforms "waffle" into "edible containers," enhancing the visual appeal of ice cream or desserts while helping stores reduce disposable packaging costs.

Users can flexibly choose from semi-automatic tabletop machines to fully automated tunnel production lines, depending on daily production volume, site size, and budget.

We provide equipment customization, installation and commissioning, and technical training. For detailed plans or trial production samples, please contact our engineering team.