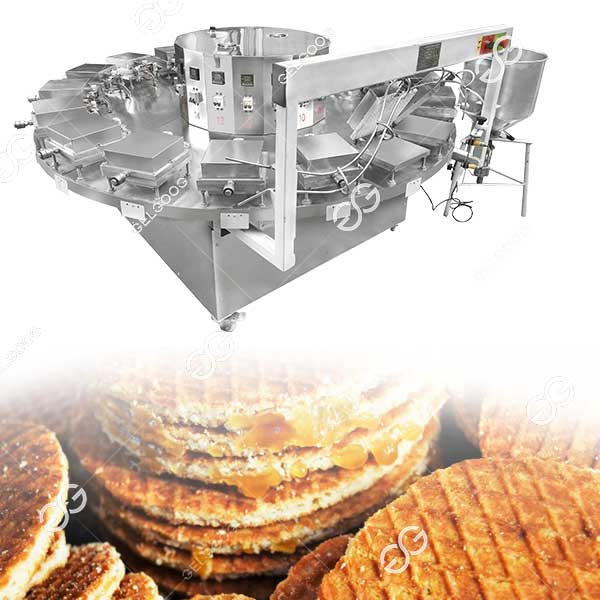

The stroopwafel thickness making machine uses rotating discs and precise electric heating to instantly transform batter into perfectly round waffle wafers of consistent thickness, golden color, and excellent texture.

This is the first and most crucial step in the automated production of high-quality waffle cones and classic Dutch stroopwafels.

How does it work?

Our machine design is intuitive and reliable, ensuring that factories can obtain perfect waffle wafers 24/7 without interruption.

- Automatic feeding and metering: The batter is automatically and evenly injected into the lower mold, ensuring that each wafer uses the same amount of raw materials, which is the basis for consistent thickness.

- Rotating pressing and shaping: The upper mold, under the precise temperature control of the electric heating system, rotates to the lower mold position, automatically closes, and presses the batter. Heat is evenly transferred, and the batter quickly forms and cooks within seconds, becoming a perfect waffle wafer.

- Automatic demolding and conveying: After baking, the mold automatically opens, and the formed waffle wafer is automatically removed and smoothly conveyed to the next process (such as cooling or the filling production line).

Why is our rotary machine a better choice?

Compared to older or smaller equipment, our industrial rotary design offers fundamental improvements:

- High output: The rotary table can be equipped with multiple mold positions, working continuously one after another without interruption. This means extremely high and stable output, meeting your large-volume order needs.

- Uniform quality: The rotary design and overall electric heating system ensure that each mold is heated completely evenly. Every waffle wafer produced has almost identical thickness, color, moisture content, and crispness, resulting in a very high product pass rate.

- Designed for factories: The robust steel structure can withstand long-term continuous operation. Electric heating is clean and precisely controlled, resulting in a better workshop environment. The machine runs smoothly with a low failure rate, simplifying your production management.

- Multi-purpose machine: By simply changing the molds, this machine can produce not only classic honeycomb waffles but also products with different patterns and diameters (from small cones to large wafers), helping you develop more new products.

The tangible benefits we offer you:

- Significantly increased production capacity: Easily replace multiple small devices or a large workforce, taking your production scale to a new level.

- Significantly reduced defect rate: Consistent quality means less waste, ensuring every bit of raw material is used efficiently.

- Build a strong product reputation: Stable thickness and texture are key to winning repeat customers and the trust of large clients.

- Make production more controllable: Automated production makes it easier to manage costs, plan delivery times, and calmly respond to market changes.

FAQ

Q: What is the price of this machine?

A: The equipment price varies depending on your specific configuration, production capacity requirements, degree of automation, and selected accessories (such as cooling conveyor belts, number of molds, etc.). We are committed to providing our customers with the most cost-effective solutions. Please provide your specific production needs, and our sales engineers will customize a solution and provide an accurate quote for you.

Q: How long does it take from placing an order to receiving the goods?

A: For standard configurations, our usual delivery time is approximately 8-12 weeks. This time includes production, assembly, factory testing, and preparation for shipment. If your order has special customization requirements, our project manager will confirm a precise delivery schedule with you immediately after the contract is signed. For urgent needs, we can also offer expedited production options.

Q: Do you provide international shipping and installation services?

A: Yes, we have extensive experience in international logistics and project execution. We can arrange door-to-door international shipping (sea or air freight) and handle all related export documents. We also provide professional overseas installation and commissioning services – our engineers can travel to your factory location to ensure the equipment is correctly installed, commissioned, and your operators are trained until the production line is running smoothly. The scope and details of the service will be clearly defined in the contract.