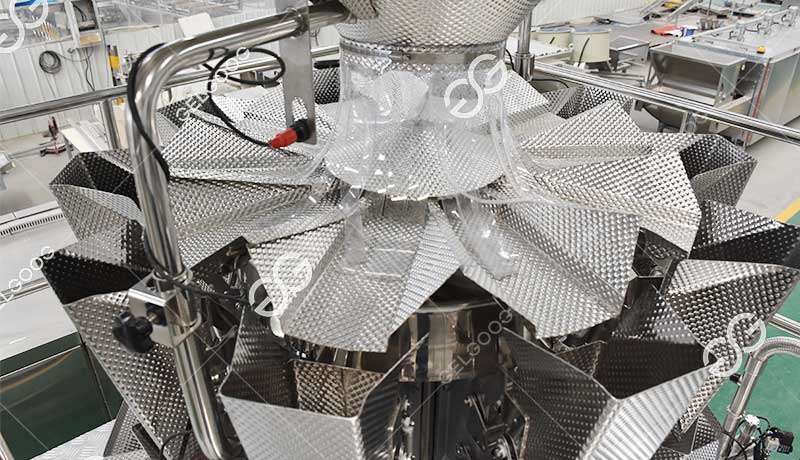

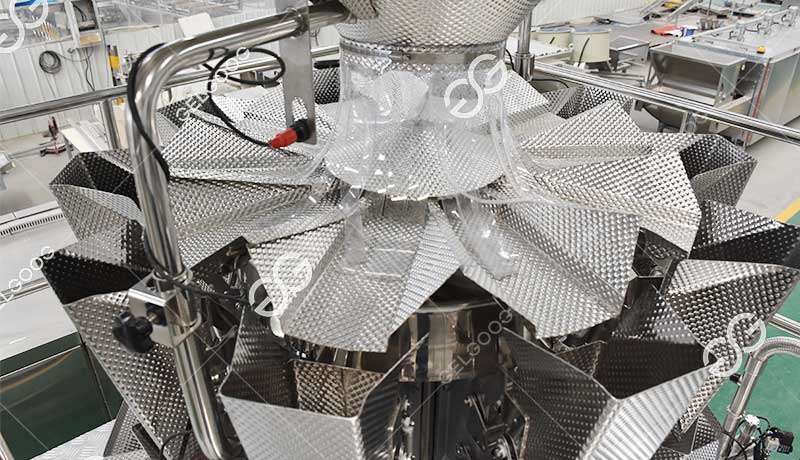

The ice cream cone packing machine with automatic weighing function is designed for factory environment, mainly used for accurate weighing and packing of ice cream cones.

Main Features of Cone Packing Machine

- Multi-head weighing design: through multiple weighing channels working simultaneously, the packaging speed is significantly improved.

- High-precision weighing: using high-precision sensors and advanced algorithms to ensure the accurate weight of each cone and meet quality control standards.

- Dynamic compensation function: can automatically adjust the impact of environmental changes or raw material differences to maintain the accuracy and consistency of weighing.

- High degree of automation: reduce manual intervention, reduce labor costs and improve production efficiency.

- Flexible adjustment: can quickly adjust the machine settings according to the size and weight requirements of different cones.

- User-friendly interface: equipped with an intuitive touch screen operation interface, which is convenient for operators to quickly get started.

Applications of Mini Cone Packing Machine

- Ice cream cone manufacturers: primary packaging of bulk cones, cakes, and waffle cones into retail or food service bags.

- Large ice cream producers: internal packaging of cones so that they can be placed in multi-packs or packaged with products.

- Snack food processing plants: Packing similar fragile, weighed products, such as mini waffle cones, cookie bars, or other small baked goods that require precise weighing.

- OEM plants: Provide accurate and efficient packaging services for multiple customers who need weighed cone products.

Advantages of Our Ice Cream Cone Packing Machine

- Improve efficiency: Automated equipment reduces packaging time and improves overall production capacity.

- Reduce waste: Accurate weighing function reduces material waste caused by uneven weight.

- Quality assurance: Standardized packaging processes ensure product quality and consistency.

- Long-term return on investment: The equipment is durable and has low maintenance costs, with long-term investment value.

- Enhance competitiveness: High-quality products and perfect packaging can enhance the market competitiveness of enterprises.

After-Sales Service of Cone Packing Machine

- Installation and commissioning: Some suppliers will provide professional installation and commissioning services to ensure that the equipment can operate normally in the customer's factory.

- Operation training: Suppliers usually provide customers with operation training to help customers familiarize themselves with the operation process and daily maintenance of the equipment.

- Technical support: During the operation of the equipment, if you encounter technical problems, the supplier will provide technical support to help customers solve the problems.

- Spare parts supply: To ensure the long-term stable operation of the equipment, the supplier will provide spare parts supply service, so that customers can replace them in time when needed.

Are you ready to transform your cone packaging process? Contact us now to discuss your specific production needs and learn how this high-performance ice cream cone packing machine can optimize your operations and increase your profitability.