For factories and enterprises aiming to scale production, understanding what the cone of an ice cream is made from—and the equipment required to produce it—is critical for efficiency, consistency, and profitability.

In this article, we break down the raw materials, production processes, and advanced machinery used to create ice cream cones at an industrial scale.

The Core Ingredients: What Are Ice Cream Cones Made From?

- Flour: Typically wheat-based, providing structure and crispness.

- Sugar: Adds sweetness and aids in caramelization during baking.

- Water: Binds ingredients and controls dough consistency.

- Vegetable Oil: Enhances texture and prevents sticking during molding.

- Leavening Agents: Optional additives like baking soda for slight aeration.

Industrial Manufacturing Process: From Dough to Finished Cone

For factories, producing ice cream cones at scale involves a streamlined, automated workflow.

- Mixing & Dough Preparation:Industrial mixers blend ingredients into a smooth, homogeneous batter. Advanced machines regulate temperature and humidity to optimize dough consistency for molding.

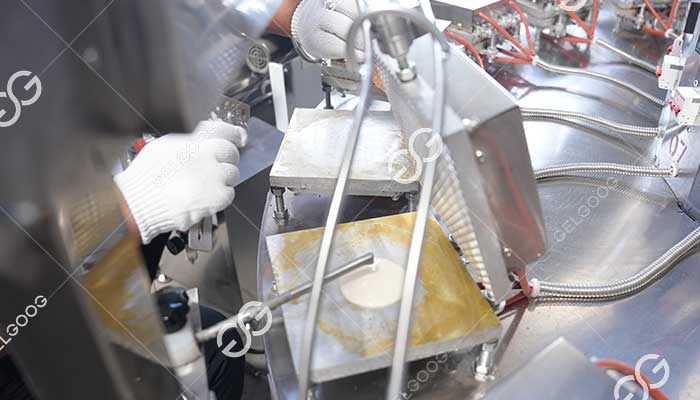

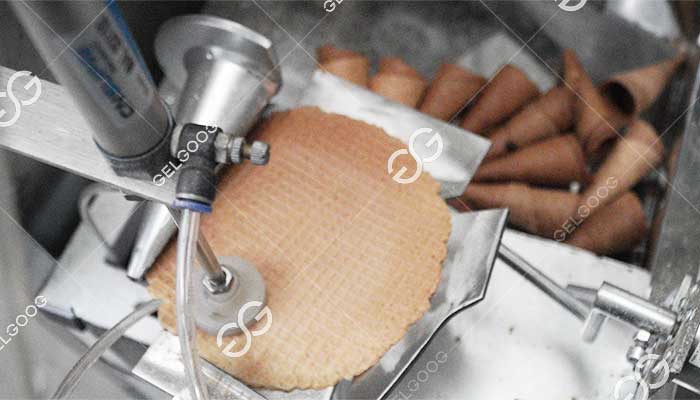

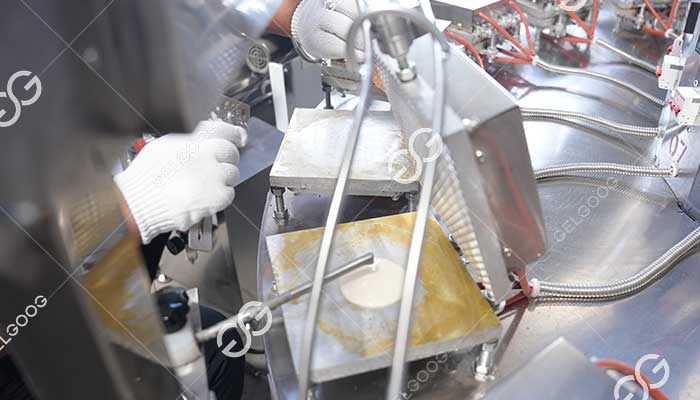

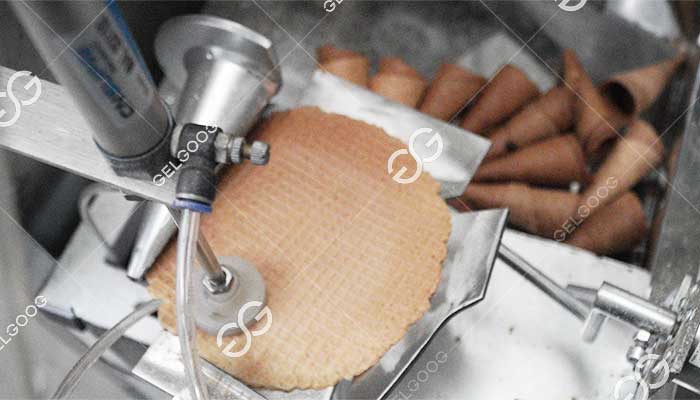

- Molding & Shaping:High-speed rotary molding machines press the dough into cone-shaped cavities. Precision heating systems ensure even cooking and structural integrity.

- Baking & Drying:Tunnel ovens with adjustable temperature zones bake cones uniformly while removing moisture. Industrial-grade ovens can process thousands of cones per hour.

- Cooling & Packaging:Automated cooling conveyors prepare cones for packaging. Robotic arms stack and wrap finished products into bulk containers.

Why Invest in Industrial-Grade Cone Manufacturing Machines?

- Speed & Capacity: Produce 10,000+ cones per hour with minimal downtime.

- Consistency: Programmable controls eliminate human error in shaping and baking.

- Energy Efficiency: Optimized heating systems reduce operational costs.

- Versatility: Adjust settings for waffle cones, sugar cones, or custom shapes.

Key Applications for Industrial Cone-Making Equipment

Understanding what the cone of an ice cream is made from is just the start. Industrial machines cater to diverse needs:

- Ice Cream Brands: Scale production to meet global demand.

- Bakery Suppliers: Expand into cone manufacturing as a B2B revenue stream.

- Food Service Providers: Offer branded cones for restaurants and franchises.

Future Trends in Cone Production Technology

To stay competitive, manufacturers are adopting innovations like:

- AI-Driven Quality Inspection: Cameras detect defects in real time.

- Sustainable Materials: Plant-based coatings for eco-friendly cones.

- Hybrid Lines: Machines that produce cones and fill them with ice cream.

Conclusion: Elevate Your Production with Advanced Machinery

Now that you know what the cone of an ice cream is made from, it’s clear that industrial-grade equipment is the backbone of efficient, large-scale manufacturing. By investing in automated mixing, molding, and baking systems, factories can achieve higher output, lower costs, and superior product quality.

Ready to upgrade your production line? Explore our range of industrial cone-making machines designed for enterprises—contact us today for a customized solution!