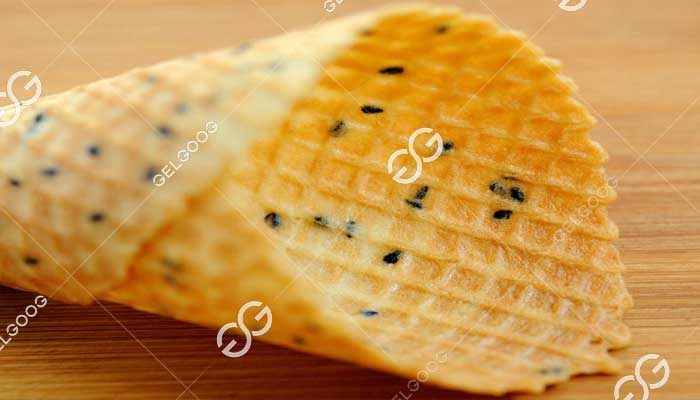

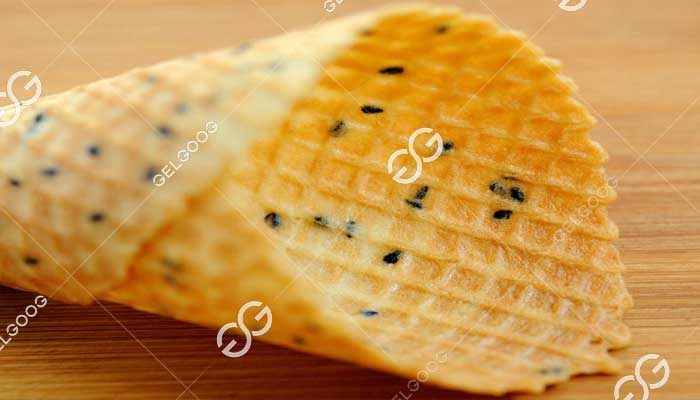

The crispy texture and perfect shape of ice cream cones are the soul of summer desserts, but are you curious about how they are produced on a large scale?

In this blog, we will reveal the whole process of industrial cone production and show you how our cone production machinery can help you create high-quality products efficiently and stably!

Raw Material Mixing: Precise Formula, Efficient Mixing

- The starting point of cone production is batter preparation. Our fully automatic mixing system can accurately control the ratio of raw materials such as flour, sugar, and water to ensure the uniformity and stability of each batch of batter.

- Through PLC intelligent control, the equipment can quickly switch recipes to meet the needs of various cones such as original flavor, chocolate, and whole wheat.

Forming and Baking: The Perfect Balance of Speed and Quality

- After the batter is injected into the mold, it enters the critical forming stage! Our cone forming machine uses high-temperature compression molding technology to ensure that the cone shape is consistent and the thickness is uniform.

- The equipment is equipped with an intelligent temperature control system, which can be accurately adjusted between 180°C and 220°C to avoid burnt or undercooked problems.

Fast Cooling and Demoulding: Zero Breakage, High Yield Rate

- The freshly baked egg cones need to be cooled quickly to maintain crispness. Our multi-layer circulating cooling line uses cold air to evenly cool down to avoid deformation or cracking caused by temperature difference.

Automated Packaging: Hygienic and Efficient, Extending Shelf Life

- The cooled egg cones enter the packaging stage. Our packaging machines are of various types and support various packaging. The equipment integrates a visual inspection system to automatically remove defective products to ensure that the products shipped meet the standards.

Services We Provide

Selecting egg cone production equipment suppliers usually considers production efficiency, product quality, cost control, and long-term cooperation value. We bring you:

- Process optimization: The equipment is specially designed for egg cones, accurately controlling parameters such as temperature and molding time to ensure product consistency and reduce scrap rate.

- Standardized output: Professional equipment can accurately reproduce the thickness and shape of the egg cone (such as waffle texture, cone angle, etc.), avoiding deformation and cracking problems that are prone to traditional manual or general equipment.

- Material adaptability: According to the characteristics of egg cone batter (such as viscosity and expansion rate), the equipment can adjust the stirring speed and baking temperature curve to ensure a crispy taste without burning.

- Flexible adaptation needs: The size of the egg cone (such as mini, enlarged) and pattern (such as brand logo embossing) can be customized according to customer needs.

Take action now and upgrade your egg cone production line!

Whether you plan to build a new factory or optimize existing equipment, our egg cone production machinery can provide you with customized solutions.