In the field of ice cream cone production, the semi automatic cone production machine has become the preferred choice of many cone production companies with its unique design and efficient operation.

It not only combines the efficiency of automated production, but also retains the flexibility of manual operation. This article will explore its characteristics and advantages in actual production in depth.

What Is a Semi Automatic Cone Production Machine?

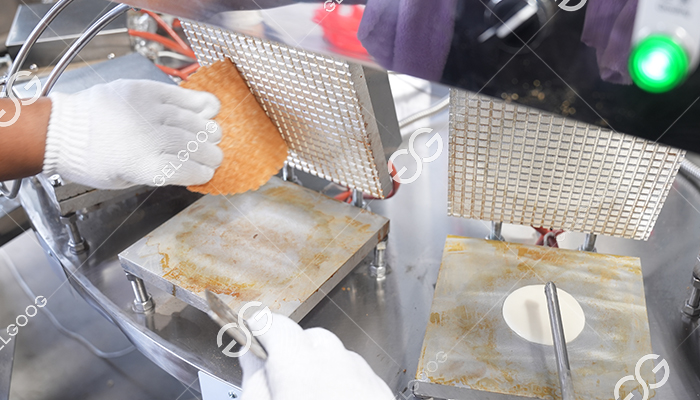

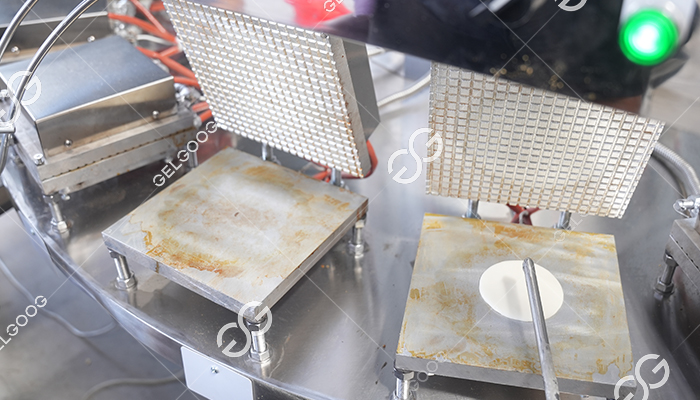

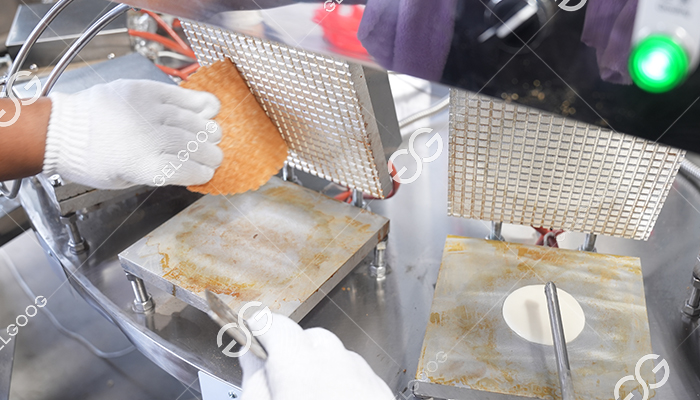

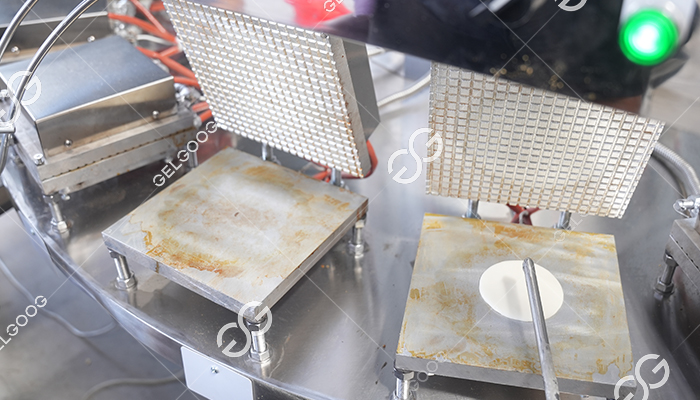

- This is a cone production equipment that combines automation technology and manual operation. It uses a rotating turntable to concentrate the key steps of cone forming and baking on one platform.

- The operator can perform operations such as raw material delivery and molding adjustment at different positions of the turntable, while the machine is responsible for completing automated processes such as baking and cooling.

Advantages of Semi Automatic Cone Production Machine

Efficient Production to Meet Market Demand

- Rapid molding and baking: The machine adopts a continuous rotation working mode, and each station can independently complete the molding and baking of the cone. This design greatly shortens the production cycle and improves production efficiency. .

- Stable quality: The machine's automated baking system can accurately control temperature and time to ensure that each cone is baked under optimal conditions. This makes the quality of the cone more stable, with a crispy taste and uniform color, reducing quality fluctuations caused by inconsistent manual operation.

Flexible Operation to Adapt to Diverse Needs

- Personalized customization: The semi automatic cone production machine retains the manual operation link. The operator can add chocolate sauce, chopped nuts and other ingredients to the surface of the cone according to customer needs to achieve personalized customization. This flexibility enables cone manufacturers to respond quickly to market changes and meet the diverse needs of consumers.

- Easy to adjust: The design of the machine allows operators to adjust the shape, size and ingredient ratio of the cone at any time during the production process. Whether it is producing standard cone cones, special lace cones or cup cones, it can be achieved by simply adjusting the mold and operating parameters.

Significant Cost-Effectiveness

- Moderate equipment investment: Compared with the fully automatic cone production line, the price of the semi-automatic turntable cone production machine is more affordable. It does not require a complex automatic control system and high equipment costs, and is suitable for small and medium-sized cone production companies. For companies that have just entered the cone market, this equipment is a very cost-effective choice.

- Reduce labor costs: Although the semi-automatic turntable cone production machine requires manual operation, its efficient production process greatly reduces labor input. Operators can complete multiple processes on one platform, reducing the number of staffing and reducing the labor costs of the enterprise.

The semi automatic cone production machine can not only meet the needs of large-scale production, but also adapt to the market trend of personalized customization, providing strong support for cone production companies.

For those companies that want to stand out in the cone market, choosing a semi-automatic turntable cone production machine is undoubtedly a wise decision.