Automatic wafer cone making machine is designed for efficient production of waffle cones and is widely used in ice cream factories and food processing industries.

It integrates advanced mechanical, electronic and temperature control technologies. The appearance is usually made of stainless steel, which is durable and meets food hygiene standards. It can not only meet the needs of large-scale mass production, but also achieve small-batch customized production through parameter adjustment.

Working Principle of Ice Cream Wafer Cone Making Machine

- Batter preparation: Mix flour, sugar, eggs, milk, cooking oil and other raw materials in proportion to make a uniform batter. The batter needs to be stirred until smooth and particle-free to ensure the uniform texture of the final product.

- Machine preheating: After the batter is prepared, start the ice cream cone making machine and adjust the temperature of the upper and lower molds. Usually, the machine will be preheated to the set temperature to ensure the uniformity of the baking process.

- Batter filling and molding: The batter is poured into the lower mold through an automatic grouting system or manually, and the upper and lower molds are closed. The batter is evenly distributed in the mold and begins to form. After the mold is heated, the batter gradually hardens and forms the shape of a cone.

- Baking: The mold is baked at a set temperature (usually 180-220°C) for 1-2 minutes. After baking, the cone will turn golden and crispy.

- Cooling and demoulding: After baking, the upper mold is lifted, the lower mold is opened, and the formed cone is demoulded by an automatic scraper or conveyor belt and slides into the cooling channel. The cone is cooled to room temperature on the conveyor belt to maintain its crispness.

Advantages of Automatic Ice Cream Wafer Cone Machine

- High degree of automation: The PLC control system is adopted, and the touch screen operation is used to realize fully automated production from batter filling to finished product collection.

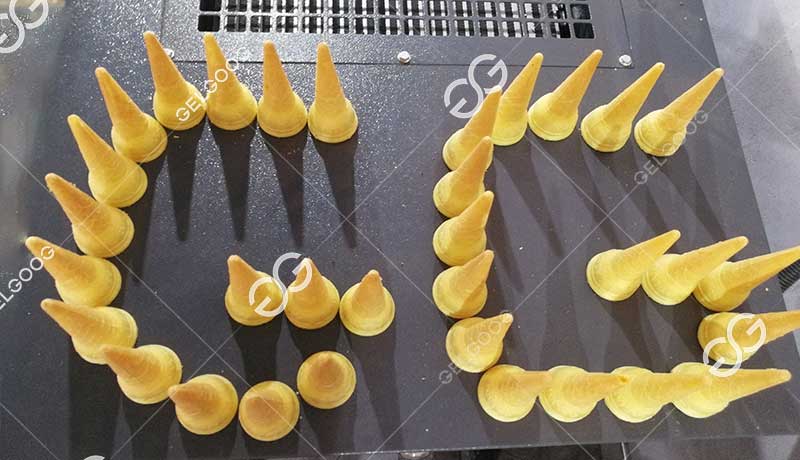

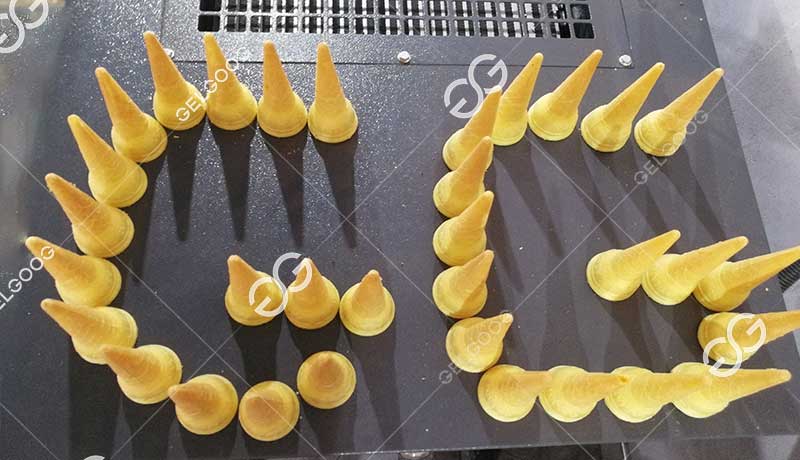

- Diversified production: The equipment can replace molds and produce wafer cones of various shapes and sizes, such as torch shape, corn shape, double head shape, flower shape, etc.

- Efficient production: The production capacity can reach 3600-9000 wafer cones per hour depending on the model.

- Food grade materials and hygienic design: The main body of the equipment is made of food grade stainless steel and aluminum alloy, and the mold is usually made of aluminum alloy to ensure food hygiene and safety.

- Easy maintenance: Modular design facilitates daily maintenance and parts replacement, reducing maintenance costs.

Automatic Ice Cream Wafer Cone Machine FAQ

Q1: What preparations need to be made before use?

- Before use, it is necessary to check whether the screw connection is loose, whether the mold is reliable, and whether the mold cavity is damaged.

- Apply edible oil on the mold surface for lubrication and demolding.

- Preheat the machine to the set temperature to ensure uniform heating

Q2: How to perform daily maintenance?

- After each use, cut off the power supply, open the mold, clean the residue to prevent mold deformation.

- Clean the mold and conveyor track regularly to prevent blockage.

- Check the electrical and mechanical components of the machine regularly to ensure its normal operation.

Q3: What are the requirements for batter preparation?

- The batter is a mixture of wheat flour, corn starch, vegetable oil, food coloring, etc., which needs to be stirred evenly.

- Using high-quality flour can ensure the best effect of the cone.