Ice cream cone baking machine is a highly efficient equipment specially used for producing ice cream cones, waffle cones and related products. These machines are widely used in ice cream factories, bakery processing plants, dessert shops, frozen food factories and other scenes.

Features of Waffle Cone Baking Machine

- Automated production: From batter injection, baking, molding to conveying, the whole process is automated, reducing manual operation and improving production efficiency.

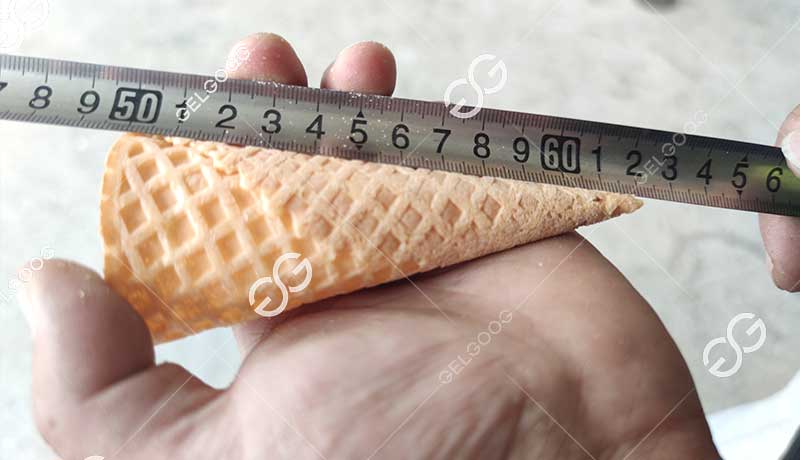

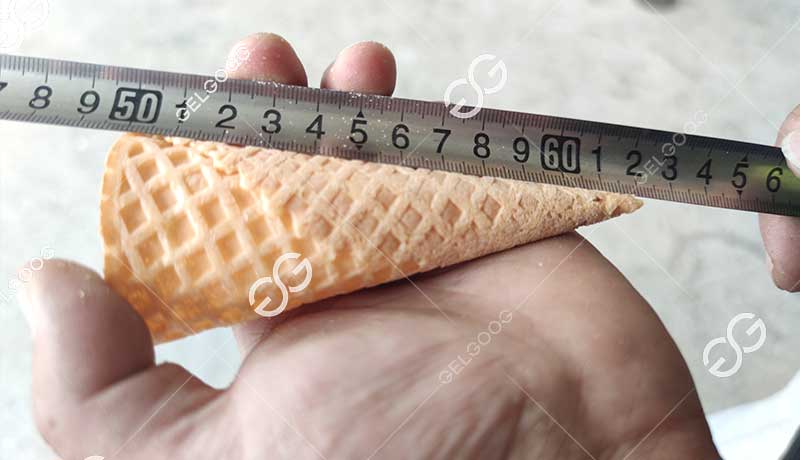

- Diversified products: By changing the mold, cones of various shapes and sizes can be produced, such as cones, bowls, waffles, etc.

- Efficient baking: The equipment adopts advanced heating technology and bakes evenly to ensure that the cone is golden in color and crispy in taste.

- Hygiene and durability: The main body is made of food-grade stainless steel, which meets food safety standards, is easy to clean and has a long service life.

- Energy-saving design: It provides two ways of electric heating and gas heating, which can be selected according to needs to reduce energy consumption.

Production Process of Ice Cream Cone Baking Machine

- Preparation of batter: Mix flour, sugar, cooking oil, starch and other raw materials into batter and pour it into the batter storage tank.

- Baking and forming: The batter is evenly injected into the baking mold through the nozzle, and the baking mold is quickly baked and formed at high temperature.

- Rolling and cooling: The baked cone is rolled into a cone shape by the rolling device and fixed on the cooling conveyor belt.

- Packaging: The cooled cone is packaged by an automatic packaging machine to ensure product quality.

Application Scenarios of Waffle Cone Baking Machine

Ice cream manufacturers: used for large-scale production of high-quality ice cream cones to enhance product competitiveness.

Bakery food factory: Produce diversified cone products to meet the needs of different customers.

Dessert shops and fast food restaurants: used to make snacks such as waffles and egg rolls to enhance product diversity

Advantages of Ice Cream Cone Baking Machine

Efficient and automated production: The ice cream cone baking machine realizes fully automatic operation from batter injection, baking, forming to rolling, greatly improving production efficiency.

Diversified product customization: The equipment supports multiple mold replacements, and can produce cones of various shapes and sizes such as cones, bowls, and waffles. The molds can also be customized according to customer needs.

High-quality finished products: Precise temperature and time control ensures uniform baking of the cones, and the finished products are golden in color and crispy in taste.

Energy saving and environmental protection: The equipment adopts an efficient heating system, usually using natural gas or electricity. Some equipment adopts insulation design to reduce heat loss and further reduce energy consumption.

Low maintenance cost: The equipment has a compact structure, easy operation, low maintenance cost, and provides online technical support to help users quickly solve problems encountered during operation.